At some point in your DIY/handyman journey, you will encounter a stripped screw. A stripped screw is a screw with a head that has become so damaged and bored out, that the screw bit on your screwdriver/drill can no longer get a good grip and thus extract it. Stripped screws occur when using the wrong screw bit whilst screwing, working too fast, or trying to insert a screw bit into a screw head at a weird angle. However they happen, they’re annoying and can seem impossible to remove.

But never fear! There are indeed solutions to this dilemma. Below we provide five different ways to extract a stripped screw. The method you use will depend on the particular stripped screw circumstance you find yourself in, as well as the tools you have on hand.

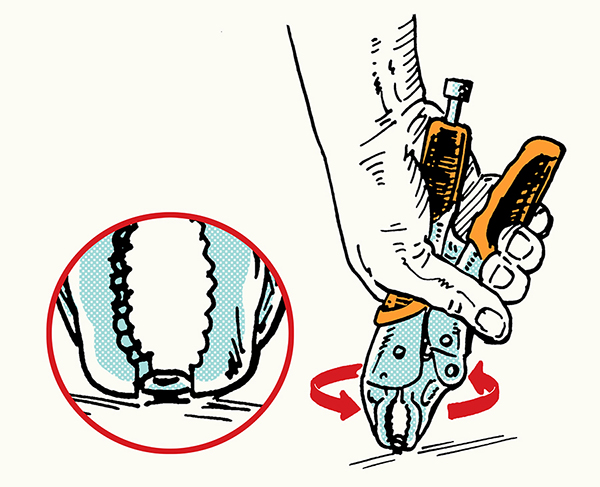

1. Pliers

If the screw isn’t completely screwed into the wood or metal, there’s a chance you can remove it with just a pair of pliers. Grip the screw head with a pair of vise-grip pliers and turn until the screw comes out.

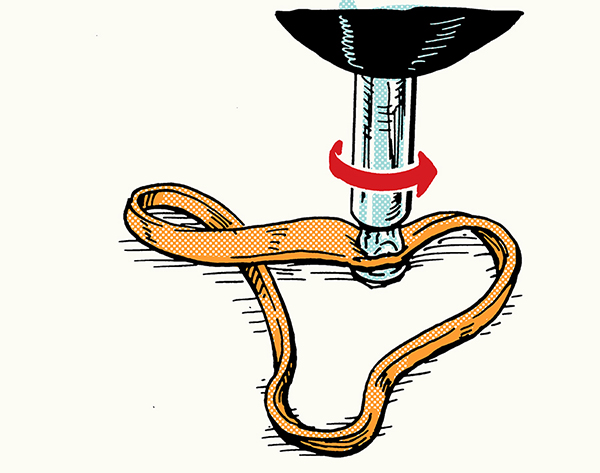

2. Rubber Band/Steel Wool

This is the first method I turn to whenever I strip a screw for the simple fact that it’s so easy to do. Sometimes all you need is a bit more grip in the stripped screw head in order to extract it.

Place a rubber band over the stripped screw and firmly insert the screwdriver into the screw head. With slow, firm pressure, extract the screw. The key to this method is to go as slow as possible. If you go too fast, you’ll just chew up the rubber band.

If you don’t have a rubber band on hand, try putting a bit of steel wool into the stripped screw head. It can also help provide some grip to help you extract the screw.

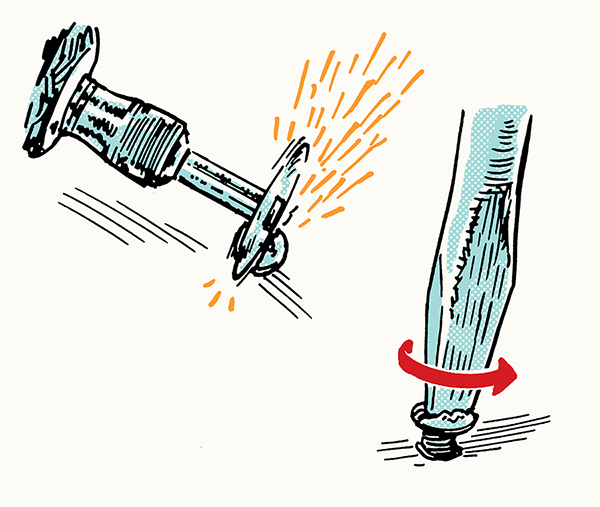

3. Dremel Tool

If you have a Dremel tool, you can cut a notch into the top of the stripped screw. Then grab a flathead screwdriver, insert it into the groove, and extract. If you don’t have a Dremel tool, you can also try cutting the notch with a hacksaw.

4. Liquid Friction

Now we enter the world of specialty products designed for stripped screw extraction. Screw Grab, DriveGrip, and other similar brands are a liquid that you apply to the stripped screw that increases the friction between it and the screwdriver. It basically does the same thing as a rubber band. It’s not a cure-all and has the best results on screws that aren’t too far stripped.

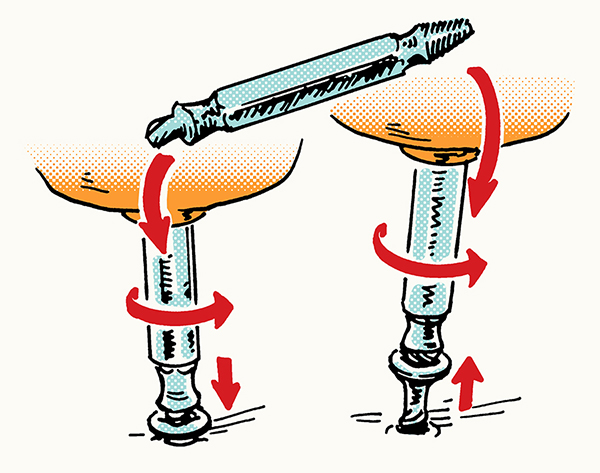

5. Screw Extractor Kit

A screw extractor kit is a special type of two-ended drill bit that is designed to remove stripped screws. You can buy kits on Amazon or at any hardware store. They’re affordable and are good to have in your workshop.

One end of the screw extractor is for drilling into the stripped screw to create a depression. With this end pointed out on your drill, set it to reverse (counterintuitive, I know) and run it at slow to moderate speed while applying firm downward pressure. Once you’ve created your impression, flip the bit so the extraction end is showing. Again run the drill in reverse with steady downward pressure to extract the screw.

There you go. How to extract a stripped screw. Next time, be more careful driving those screws, dude.