Editor’s Note: This is a guest article by Michael Magnus.

It may seem like sewing is an exclusively feminine pursuit (outside the tailoring profession), but dating back to the Paleolithic age, rudimentary sewing techniques were a vital necessity for staying alive. Sewing isn’t just about making decorative doilies, but also knowing how to quickly stitch something together for survival with minimal gear and maximum strength.

You’ve probably noticed that when you tear a seam on your clothing, it’s easy to accidentally end up tearing out at least 5 or 6 stitches. This is because sewing machines utilize a sewing method called the “lock stitch,” which creates a chain reaction when a stitch fails. If you want something that’ll stand firmer against failure, you’ll want to use a different method: the saddle stitch. This sewing methodology used by saddle makers for generations is more durable because where one stitch is broken, only one stitch is broken.

The saddle stitch is ruggedly functional because you can create it using a variety of improvised tools, and it can be used to patch/attach/close a variety of thick materials; whether repairing a tear in a tent, fixing a hole in a sleeping bag, or making a sheath for a hatchet, knowing how to saddle stitch is a skill that comes in handy.

For this tutorial, we’ll be demonstrating this hand sewing technique on one of the toughest materials you can work with: leather.

Let’s get sewing like a man.

Tools Needed

- 2 sewing needles

- Thread, preferably waxed (if not pre-waxed, you can wax it yourself with beeswax, a candle, etc.)

- Ice pick, sewing awl, or hammer/nails

- Binder clips, small clamps, or something of the sort

- Fork

- Pen (optional)

To illustrate this stitching method, we’ll be using two pieces of vegetable tan leather. This material may be thicker than a lot of the other materials you may work with; however, if you can replicate this method with resilient leather, chances are it will work elsewhere. This is can be handy for being able to repair canvas or cloth; the same basic concepts and techniques apply.

Step 1: Preparing the Leather

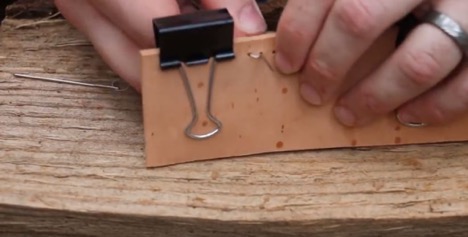

Often one of the most challenging parts of hand sewing leather is keeping the two pieces from slipping so that the stitching stays straight. You can accomplish this without binding; however, you’ll get cleaner results with a little assistance. I’m going to use binder clips here, but you could use an adhesive or even nails. This binding is particularly helpful if you are repairing something like a tent or a sail, where the repair has to be made where it stands.

Starting with the rough sides together and the smooth sides out, align the outside edges and use the binder clips to hold them together. This will help ensure that the holes for the stitching align and keep everything straight.

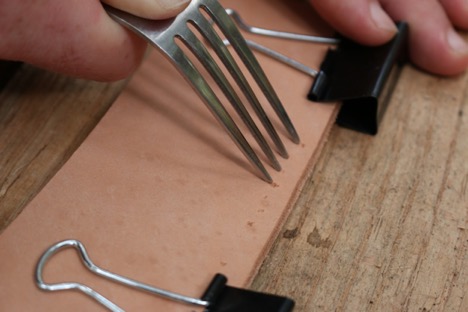

Step 2: Set the Spacing

What we want to do is give ourselves somewhat even spacing to work from. A fork will generally do the trick for this. It may not be perfectly straight, but it gets the job done. The aim is to create a guide by making impressions on the leather of what the spacing needs to be and where the holes will go. To do this, you’ll want to overlap the last impression (making only 3 new marks each time) to ensure even spacing.

If you are using this method on canvas or other material, you can use the same technique with a fork, but mark the spacing with a pen or whatever you may have available.

Step 3: Creating Holes

A sewing awl is ideal to puncture holes, but again, you may be limited on available tools. If you have access to something like an ice pick or a sturdy shank, that would work. With the right tool, it actually cuts the leather for sewing, whereas an ice pick or a shank will tear a hole. Ultimately, having a sewing awl on hand might create a longer-lasting repair, but you have to work from whatever you have available.

There is another option too: hammer and nails. By finding a log or piece of wood, you can secure the two ends of your materials together by hammering a nail to hold it in place. From there, you can replicate the fork method for marking stitch lines and then hammer a nail to create the holes for stitching.

Knives typically don’t work very well for this step. You ideally need a relatively round hole and the puncture from a knife is elongated. If it’s all you have, you may be able to complete this step by creating knife punctures perpendicular to the edge of the material to make sure that you can maintain the spacing. This leaves more room for the stitch to tear out, but, again, use what you have on hand.

Now to actually make the holes: Utilizing the pattern made with the fork, pierce all the way through the leather. Depending on how thick the leather is and how sharp your piercing utensil is, you may need to puncture from each side. If so, push far enough through that you can start to see where the hole would come through and then turn the leather around to finish creating the hole from the other side.

Step 4: Sewing

Now that we have our holes in each piece of leather, we are going to prepare the thread. For this saddle stitch method, you’ll want to measure and cut at least 3.5 times the distance of the length that you plan on sewing.

Optional: If your thread is not waxed, you might consider waxing the thread at this time with beeswax or candle wax. To do so, hold the thread between your thumb and the wax and pull it a few times. The friction from the pressure will help the thread take the wax, which will help prolong the life of the thread and help prevent the stitch from loosening.

You’ll want to start with a needle on each end of the thread, and the first thing you’ll do is push this first needle through the first hole. After you’ve pulled a threaded needle through the first hole, even out the amount of thread on each side of the material so that each needle is roughly equal distance from the piece of leather.

The thread should go through relatively easily, but depending on the size of the needle versus the size of the hole, you may consider using some pliers to help pull the needle through. If you do use pliers, make sure that you are pulling the needle straight, because pulling through at an angle is likely to break your needle.

Once you’ve set up, you’re going to start sewing figure eights back and forth through the holes. You’ll start by taking the first needle through the second hole, going through both pieces of leather, and then taking the second threaded needle to go through that same hole in the opposite direction. In theory, the holes should be relatively lined up on each piece of leather; however, you may sometimes need to adjust slightly to find the right angle to go through both holes.

Note: If one needle passes through the thread of the previous pass, you may encounter some problems pulling the stitching tight. To avoid this, after the first needle has passed through, pull the thread to one side to create a clear passage for the second needle.

You will continue to do this all the way down your guide holes, pulling the thread firmly to tighten the stitch with each pass through. For the last holes, we will sew through them twice to “lock†the stitch (more on that in just a bit), so this is a good time to evaluate if you think the needle will pass through easily a second time. If you’ve had no trouble up until this point, you may be fine. However if you have experienced some struggle getting the needle through, you’ll probably want to widen the last few holes with your awl or icepick to make sure that they pass more easily.

To complete the stitch, go through the final holes in the same figure 8 pattern that you have been using. Once you get to the end, you will double back through at least two sets of holes with this same method. Again, you may find it little more difficult to get it through since these are already relatively small holes and we will have filled them with twice as much thread.

Once you have stitched back twice, pull the thread tight and trim the thread.

Congratulations, you’ve completed the saddle stitch. It’s not always pretty, but it’s very durable and functional. This information will come in handy when you inevitably need to stitch something when camping, sailing, or surviving the zombie apocalypse.

Watch the Video

______________________

Michael Magnus is a digital advertising lecturer, consultant, and freelancer based in North Texas. When not teaching or with his family, Magnus promotes the art of leatherworking as a recreational leathercraft historian and content creator with the Elktracks Studio Foundation.