You can do a lot with rope.

Tie stuff down; pull stuff out; hoist things up.

Without rope, humans wouldn’t have been able to sail across the globe, climb the tallest mountains, or build epic monuments and skyscrapers.

It wouldn’t be too far fetched to say that rope made civilization possible.

Yet despite the profound impact rope has had on humanity, and the use you’ve likely gotten out of it personally in the mundanities of your own life, you probably know very little about these mighty functional cords. What’s rope made of? How’s it made? When would I want to use one kind of rope over another?

Below we rope the answers to these questions.

Types of Rope Construction

Ropes are constructed in 2 primary ways: laid and braided.

Laid Rope

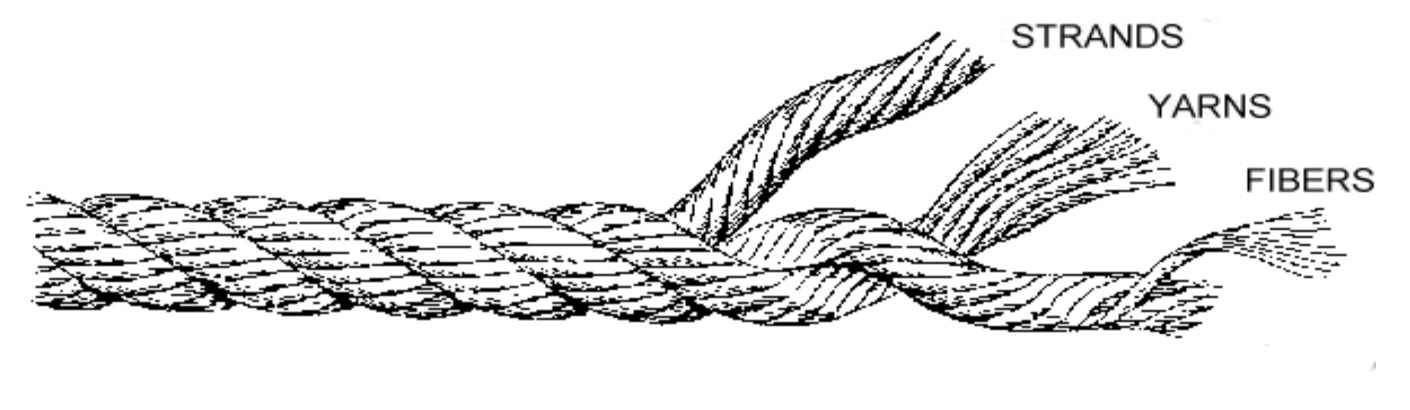

Laid rope is also known as twisted rope because it’s made by twisting fibers together.

For the majority of world history this was the most prevalent type of rope construction. Laid rope is made in a 3-part process: First, fibers are twisted into yarns. Next, the yarns are twisted together to form strands. Finally, these strands are twisted together to form rope.

To keep laid rope held together, all this twisting is done in opposite directions. The twist of the yarn is opposite to that of the strands, and the twist of the strands is opposite to that of the rope.

Laid rope comes in 2 kinds: 3-strand and 8-strand.

Three-strand laid rope is made from 3 strands twisted around each other. It’s the most common type of laid rope.

Eight-strand laid rope is made from 2 pairs of right-twisted and 2 pairs of left-twisted strands.

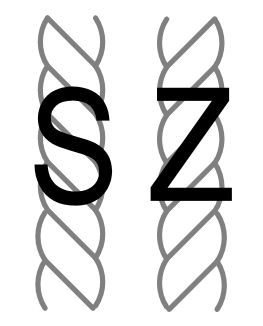

Laid rope is described as S-laid (left-laid) or Z-laid (right-laid) according to whether the twist follows the line of the center part of the letter S or Z. Most 3-strand rope is Z-laid (right-laid).

If you were a Boy Scout, you likely had the chance to make some 3-strand laid rope with a rope-making machine like this one.

Laid rope has a bit of stretch in it, which came in handy on ships when they anchored and moored. Many boats still use laid rope for these tasks.

Splicing laid rope is also much easier to do than splicing braided rope.

The downside of laid rope is that it can partially unwind with use, which can result in kinking or can cause spinning if you’re using the rope to suspend an object.

Braided Rope

Instead of twisting strands together to form rope, braided rope is, as the name readily suggests, made from strands that are braided together.

Braided rope has been around for centuries, but wasn’t very prevalent until the Industrial Revolution, when weaving and braiding became mechanized. And it really wasn’t until WWII that braided rope became a mainstay in the world of rope.

Braided rope comes in several varieties:

Single braid. Consists of 8 or 12 strands that are braided together in a circular pattern. One-half of the strands go clockwise, the other half go counter-clockwise. It creates a tubular-shaped rope.

Double braid. Also known as a “braid on braid†or “marine rope.” It has a braided core with a braided sheath around the core. It’s basically a rope within a rope. The inner and outer rope both provide strength in bearing load. It’s a strong, durable rope that’s resistant to abrasion and doesn’t easily kink. It also holds its shape really well. It’s used on boats quite a bit.

Kernmantle. Similar to a double-braid rope, but instead of the inner core being braided, the strands in the inner core are either twisted or simply run parallel together. The outer layer is tightly braided, giving it higher abrasion resistance. Kernmantle is actually German for “core†(kern) and “sheath†(mantle).

Kernmantle rope is designed so that the inner core takes most of the load when being used. The outer layer is mostly there to protect the inner core.

Paracord is an example of kernmantle rope. Cut a bit open and you’ll see that the outer layer contains an inner core of twisted strands.

Kermantle rope is often used in rock climbing, repelling, caving, tree climbing (as in the type performed by professional arborists), and fire rescue.

There are 2 types of kernmantle rope: dynamic and static. Dynamic kernmantle is used primarily in rock climbing. It provides a lot of stretch, which comes in handy when a climber falls. The stretch allows the dynamic rope to absorb the energy from a fall, reducing its amount of force, and making the stop at the end of the fall a little less jarring. The energy absorption also reduces the likelihood of the rope snapping.

Static rope is less stretchy than dynamic rope and is used mostly by repellers, cavers, tree climbers, and in rescue work.

Rope Materials

Ropes come in a variety of materials. Most modern ropes use synthetic materials like nylon and polypropylene, while rope made from natural materials has largely been relegated to decorative purposes.

Synthetic rope has come to predominate because of its superior strength and higher resistance to abrasion and the elements. One of the downsides of synthetic rope material, however, is that it can become slippery when wet, making knot tying more difficult.

Natural Rope Materials

Manila. As one of the strongest sources for natural rope, this classic material was the most common one to be used before the advent of synthetics. Manila rope is often referred to as “hemp rope,†but the fibers actually come from the leaves of the abaca plant.

Manila rope shrinks when wet; consequently, a new manila rope was often first immersed in water and dried so it would shrink to size before use. While commonly used on sailing ships, manila rope does deteriorate and rot with extended exposure to saltwater.

Back in the Wild West days, manila rope was the favored rope material for hangings. It’s probably the kind of rope you climbed in gym class too.

Hemp. While manila ropes are often referred to as hemp ropes, even though they’re not, there are actually ropes made from hemp. Similar in strength to manila, hemp has a smooth, linen-like feel. Sailors of yore would often use hemp rope for nautical purposes, tarring it to help prevent rot.

Cotton. Cotton rope is smooth and soft and is great for practicing your knot tying or to use as a clothes line. Beyond that, it’s not a great rope material, as it’s not very strong or durable and rots quickly in the elements.

Sisal. You’ve seen sisal if you’ve bought some twine. It’s a coarse, strong, durable fiber. While it’s primarily used to make twine (considered a durable thread because of its small diameter), you can buy full-on sisal ropes too.

Jute. Jute is the second-largest fiber crop after cotton. It’s inexpensive and fairly strong, but rots easily and loses its strength when wet.

As mentioned above, all of these natural fibers are primarily used today for decorative rather than functional purposes.

Synthetic Rope Materials

Nylon. This was the first synthetic material used to make rope, and continues to be the most common material used in synthetic ropes today. It’s strong and durable but loses some strength when wet. Nylon has a bit of stretch which makes it a good material to use for dynamic climbing ropes.

Polypropylene. The most inexpensive of synthetic materials, as well as the weakest and most lightweight. Polypropylene’s lightweight nature allows it to float in water, and it also resists water absorption and shrinkage when wet. Due to its water-friendly traits, polypropylene is often used in water sports like waterskiing.

Polyethylene. Like polypropylene, polyethylene floats in water. Polyethylene has a better abrasion resistance than polypropylene. It’s also used in water sports as well as to make fishing nets.

Polyester. It’s about as strong as nylon when dry, and stronger than nylon when wet. Polyester provides some stretch.

High-tech fibers. Rope is also made from materials like kevlar (the bulletproof stuff) and high-modulus polyethylene. These materials are about 3 times as strong as nylon and have very little stretch. They’re highly resistant to water, making them a good rope material for sailing. The downside to ropes made of high-tech fibers is that they’re really expensive.

With just a few minutes of reading, you now know more about rope than most people will in their lifetime. Tune in next time when we tackle how to take care of and store your rope.

Sources:

Tags: Knots